Where to Get Sheet Metal Parts

Ordering Sheet Metal Parts

The sheet metal fabrication industry is large, but fragmented. Across the United States, there are on the order of 65,000 metal fab shops, from garage shops to massive, multi-factory service centers. Service availability, quality, lead-times, quoting workflow, and a thousand other variables are going to affect customer experience, and no single shop is likely going to be a perfect fit.

We continue to expand our capabilities to meet the needs of more customers, but it's a journey we take a step at a time. In the mean-time, there are other options and we encourage customers to shop around. It may be that we aren't a perfect fit yet, but here's a review of what we think are excellent options. We naturally aren't unbiased, so our review of other vendors might not tell the full story.

OSH Cut

OSH Cut is a on-demand sheet metal cutting and bending service based in Orem, UT.

We set out in 2018 to make it easier to order laser-cut and bent sheet metal parts. Our online instant quoting service and rapid response times mean you can often have parts in-hand before other shops have even provided a price.

OSH Cut is set up to make your on-demand prototyping and production jobs easier. Our online quoting system allows you to upload and quote many parts simultaneously, accepts your pre-nested drawings, provides fully-nested quotes to get you the best pricing, and provides volume discounts at the job level. More parts mean better pricing, even across multiple unique parts and materials.

Our online system not only provides instant pricing, it also reviews your parts to highlight potential issues that could affect production. Bent parts are also analyzed to make sure we can make them with our tooling, and you can watch a bending animation to see how your parts will form right in your web browser. If there are problems, you can see them right away.

Finally, our instant 3D model support is unrivaled. You can simply upload a folded sheet metal part and our system will unfold it to create a flat pattern, adjust bend radii as needed to match our tooling, and show you both the original model and the part as produced by OSH Cut so that you can make sure everything is correct before ordering. No need to spend hours creating a flat pattern and making sure it matches your shop's tooling and capabilities.

Advantages

Instant online prices for cut and bent sheet metal parts

Instant online design review

Guaranteed lead-times as short as same-day

Easy to upload and order any number of parts all at once

3D model support with automatic sheet metal unfolding

Fully-nested prices ensure that your jobs are quoted competitively

Job-level volume discounts mean you save money on larger jobs

Limitations

OSH Cut is not (yet!) a full-service fab shop. Operations like coining, hardware insertion, welding, powder coating, anodizing, and silk screening are not currently available. Some common sheet metal operations like hemming are also not yet supported, but we'll get there.

OSH Cut's pricing for very small orders is good compared to the industry in general, but some competitors may have lower prices and shorter lead-times for small, light, unbent parts

Shipping adds cost and delay compared to local vendors

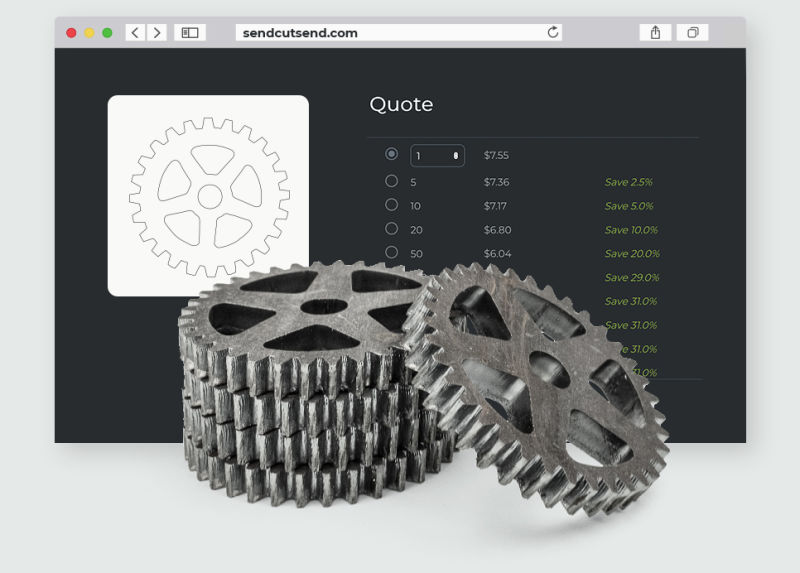

SendCutSend

SendCutSend got started at about the same time as OSH Cut, making industrial-class laser cutting equipment available to everyday people. As of March 2022, SendCutSend is an excellent source for small and mid-sized parts parts in low quantities. Their part quality, aggressive small-batch pricing, short default lead, and free shipping make them great for getting small parts, fast.

Our perception is that SendCutSend is optimized for small, light parts with simple bends, minimal quantities, and relatively few unique parts per order (at least in terms of their instant quoting service). For that class of parts, their pricing and lead-times are fantastic. We wholeheartedly recommend that you try them out! So far, our experience has been that their pricing is less competitive for large jobs, big or heavy parts, parts that would benefit from nesting, or jobs with lots of different parts.

Advantages

Instant online prices for cut and bent sheet metal parts

Excellent prices and fast average lead-time for small parts and low quantities

Value-add services like tapping and powder coating available

Multiple shops in the US for faster regional shipping

Great order status communication, with an app showing production status on-demand

Limitations

No guaranteed lead-time options available

High prices for larger parts and orders

Bending supported, but only up to 3 bends per part. "Window bends" aren't allowed.

No 3D model support or 3D part view (lots of prep time and complexity for 2D flat patterns)

No instant online design review

No nested pricing

No job-level pricing

Poor systems for quoting multiple parts

Protolabs

Protolabs has been manufacturing parts for over two decades now. They got started in quick-turn injection-molding, and expanded thereafter to add CNC machining and 3D printing services. Protolabs acquired RAPID Manufacturing in 2017 to add sheet metal fabrication to its list of services.

While Protolabs doesn't offer instant quoting on sheet metal parts, their response-time is usually measured in hours. That's not as good as an instant price, but far better than the industry norm. Our experience has been that while Protolabs' lead-times are great, their prices are extraordinarily high. Additionally, their ordering workflow isn't well-suited to quoting and ordering sheet metal parts. Nesting, multi-part jobs, and job-level pricing aren't directly supported.

Advantages

Fast quoting response times

Many value-add services

Excellent lead-times

3D model support

Limitations

Expensive

No nested pricing

No job-level pricing

No automated design review on sheet metal parts

Poor systems for quoting multiple parts

Xometry

Xometry provides instant quoting and brokering for a variety of manufacturing services, including sheet metal. Xometry is unique in this list because it isn't actually a manufacturer - its system produces instant pricing, and Xometry assigns the job to a shop to do the work when an order is placed. Based on their public financial reports, they target a gross margin of ~ 25% (a markup of 33%).

At OSH Cut, we've used Xometry with great success. We've used the service on multiple occasions to order machined parts to support our sheet metal operation. Our experience has been entirely positive.

To-date, Xometry's sheet metal service isn't generally competitively-priced. Xometry's automated quoting engine often charges 2x to 5x more than OSH Cut. In fact, OSH Cut has filled many Xometry orders for Xometry-contracted shops (eg. a customer orders from Xometry, who contracts it to a Xometry network shop, who contracts it to OSH Cut).

On the other hand, Xometry can utilize it's large shop network to offer expansive value-add services, often with great locality. For customers who aren't cost-sensitive, Xometry may represent an excellent source for simple purchasing.

Much like Protolabs, Xometry's systems are not well-suited to quoting sheet metal jobs in particular. Multi-part jobs, nesting, and job-level pricing aren't supported in any way.

Advantages

Instant online quoting

Many value-add services

3D model support

Large network of shops, many of them local

Limitations

Expensive

No direct contact with manufacturer, which can complicate customer support and quality

No nested pricing

No job-level pricing

No automated design review on sheet metal parts

Poor systems for quoting multiple parts

Big Blue Saw

Big Blue Saw has been cutting flats for customers since 2005, initially with only a CNC waterjet. Since then, Big Blue Saw has added laser cutting for a subset of materials. Incidentally, Big Blue Saw was purchased by Xometry last year for access to its quoting software and extensive library of customer parts.

Big Blue Saw provides instant pricing, and offers all the advantages you'd expect from a waterjet service - excellent quality, zero heat-affected area on material and no heat-related warping, and ability to cut virtually any material. The downsides are similarly related to waterjet cutting. Operating costs on a waterjet are high, so parts tend to be more expensive.

Advantages

Instant online quoting

Excellent cut quality

Limitations

Expensive parts

Only blank cutting offered - no bending or other value-add service

No nested pricing

No job-level pricing

No automated design review

Poor systems for quoting multiple parts

Local Shops

There are thousands of shops that provide sheet metal services, and probably more than one near you. We naturally can't say what your experience will be with local shops, and we hope that you have a local contact that can get you what you need quickly, with excellent quality, and at a reasonable price. We were motivated to start OSH Cut precisely because of inconsistent local shop experience, but that doesn't mean your circumstances will be the same!

Industry averages can tell a disheartening story. In the FMA's 2020 Financial Ratios & Operational Benchmarking Survey, one in three shops reported taking on average more than five days to provide quotes. Only one quarter of shops reported taking 1 to 3 days, and no responding shops claimed to do it in less than one day.

But there are always outliers. Some local shops will have their processes dialed in and their customer support top-tier. And in fairness, shops focusing on mass production will reasonably take longer to quote. When producing millions of parts, it is worth taking the extra time to make sure everything is exactly right.

Advantages

Local. Easy to build relationships

No shipping costs

Limitations

You have to be lucky enough to find what you need nearby!

No instant quoting

Summary

In 2022, customers have lots of options for getting their sheet metal parts manufactured. We've highlighted a few options. At the end of the day, having a diverse set of choices is great for spurring innovation, great for diversifying supply chains, and great for customer experience. We encourage customers to shop around and choose the service that best meets their needs.