How Sheet Metal Bending Works

OSH Cut offers air bending services in steel, stainless, aluminum, and copper, with metal thicknesses up to 1/4".

What is Air Bending?

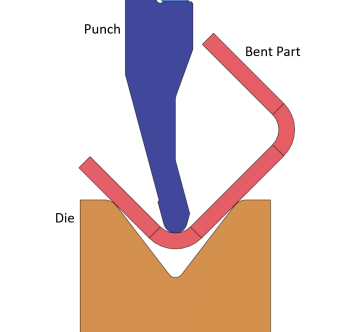

Air bending is a method of forming sheet metal using a punch and die. In a part produced using air bending, the metal is placed between a punch and a V-die as shown below:

As the press brake forces the punch and the die together, the metal folds where the punch makes contact with the part. The part itself only touches the punch on the bend line (for uploaded flat patterns) or the center of the bend radius (for 3D models), and the v-die only touches the part on the edges.

Other Operations

Sheet metal can be formed in many other ways. Features like louvres, chamfers, seams, hinges, hems, and non-cylindrical forming can be performed with special tooling. Hardware insertion (like PEM nuts) can be added to sheet metal designs, and parts can be painted, anodized, or powder coated to produce consumer-ready, finished parts.

At OSH Cut, we are sorry to say that we currently only support air bending. We intend to add more fabrication services, a step at a time. Please contact us at support@oshcut.com if you have any questions!